Customized industrial ovens and furnaces built based on your condition and specifications. Custom

designed and manufactured for processes that never existed before, and

our machines are borned with heats recycling system to reduce energy consumption.

Used for solar industry, for film curing, and to help glass gradually cool down. To improve production efficiency, and yeild. Fully automation, PLC control conveyor oven.

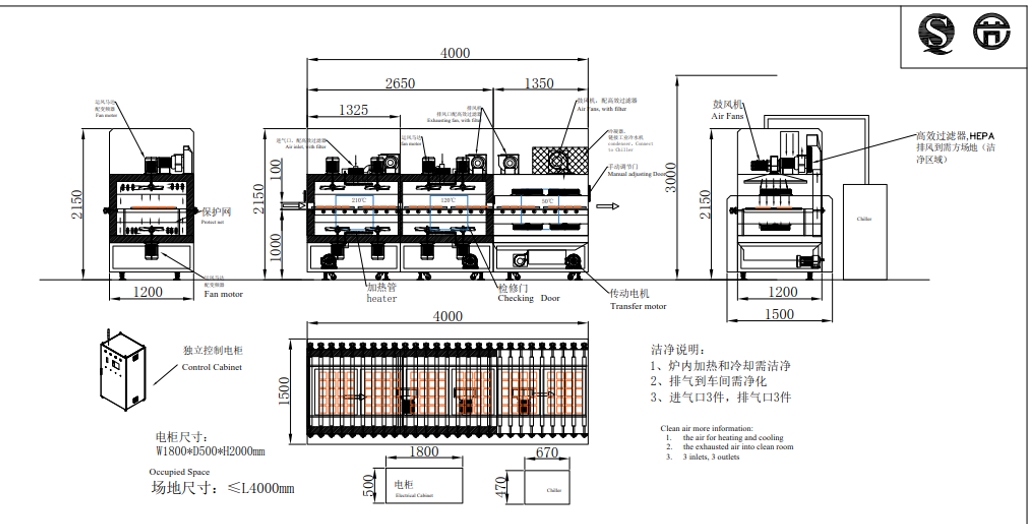

Outer Dimension (around): just the main body total length 4000*Width 1500* Height3000mm±25mm, excluding air cooler. (without condenser and control cabinet)

Used to : Cool the substrate from 300℃to 50℃, with C/T 72s.

Equipment includes:

The whole line equipment is one line, one layer, with net height of the feed port is about 100mm

Control cabinet

Including the condenser, the total height should be within 3meter

The roller conveyor from the ground is 1000±25mm

Total power: 60KW

Material used by Oven:

Shell: Made from 1.5mm carbon steel, with painting for corrosion resistance and easy cleaning. The surface should be smooth without any burr.

Chamber: For heating chamber, Made from 1.5mm #304 Stainless Steel for corrosion resistance and easy cleaning. The heating sections use 100K thickened aluminum silicate wool for non-combustibility and strong heat insulation, with a thickness of 100mm.

Body frame of the oven: Made of 50*50*2mm square steel, maintains the bearing strength of each surface inside and outside the box, and retains the coefficient of thermal expansion and contraction, which can prevent the box from deforming.

Conveyor:Quartz Ceramics Roller, diameter is AroundΦ45mm, 3 independently driven conveyors, the first section is driven by 0.37KW Siemens servo motor, available for fast material inputting & outputting and uniform constant movement.

Condensor with chiller: to provide cooling air. If there is no industrial cooling water, this module could be a good solution.

Heating System:

SS 304 heating tube, hot air convection system, thermo controller with PID, Automatic constant temperature.

PLC system:

Independent control panel, 1200PLC, with 12' HMI, Kanbus communication available.

Safety function, CE certificate.

Keywords: roller conveyor oven, hot air convection tunnel, glass heating conveyor oven

If you have any questions about the subscription or are not sure which plan is right for you, contact our team and let’s schedule a call.

+8613771727936