The latest news can be found here. Check back often for the latest

and greatest from Etek.

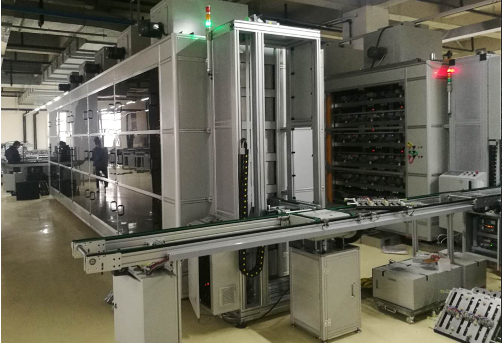

By running components at controlled temperatures for extended periods, aging ovens help manufacturers identify early failures that standard testing can miss. For battery packs, this means validating thermal stability and safety. For motors, it ensures insulation systems and materials hold up over time. And for power electronics, it confirms long-term performance under heat and load.

In EV production, aging ovens help:

Improve consistency and lifespan of battery modules and packs

Verify durability of motor windings and insulation

Ensure stable performance of inverters, converters, and control electronics

As EV production scales up, manufacturers also need aging ovens that deliver precise temperature uniformity, reliable long-duration operation, and smooth integration with automated lines.

Normally, the temperature is around 80C, precisely control with test equipment inside.

If you have any questions about the subscription or are not sure which plan is right for you, contact our team and let’s schedule a call.

+8613771727936